- Policy changes have injected uncertainty into procurement operations. Tariffs on imports are leading to halted orders and forcing companies to seek alternative sourcing options quickly.

- Procurement execution relies on specialized knowledge and supplier relationships. Many of these functions are carried out without the use of integrated systems, leading to inefficiencies such as redundant supplier contracts or missed opportunities for cost savings.

- Manual processes and lack of advanced analytics slow operations, increase errors, and limit visibility into supplier performance and cost-saving opportunities.

Our Advice

Critical Insight

CIOs play a critical role in enabling procurement transformation by modernizing infrastructure and ensuring interoperability between platforms. A modern procurement technology landscape not only boosts operational efficiency but also empowers the organization with accurate, timely insights that are essential for navigating market volatility.

Impact and Result

Gain a detailed methodology to select the right procurement technologies and vendors.

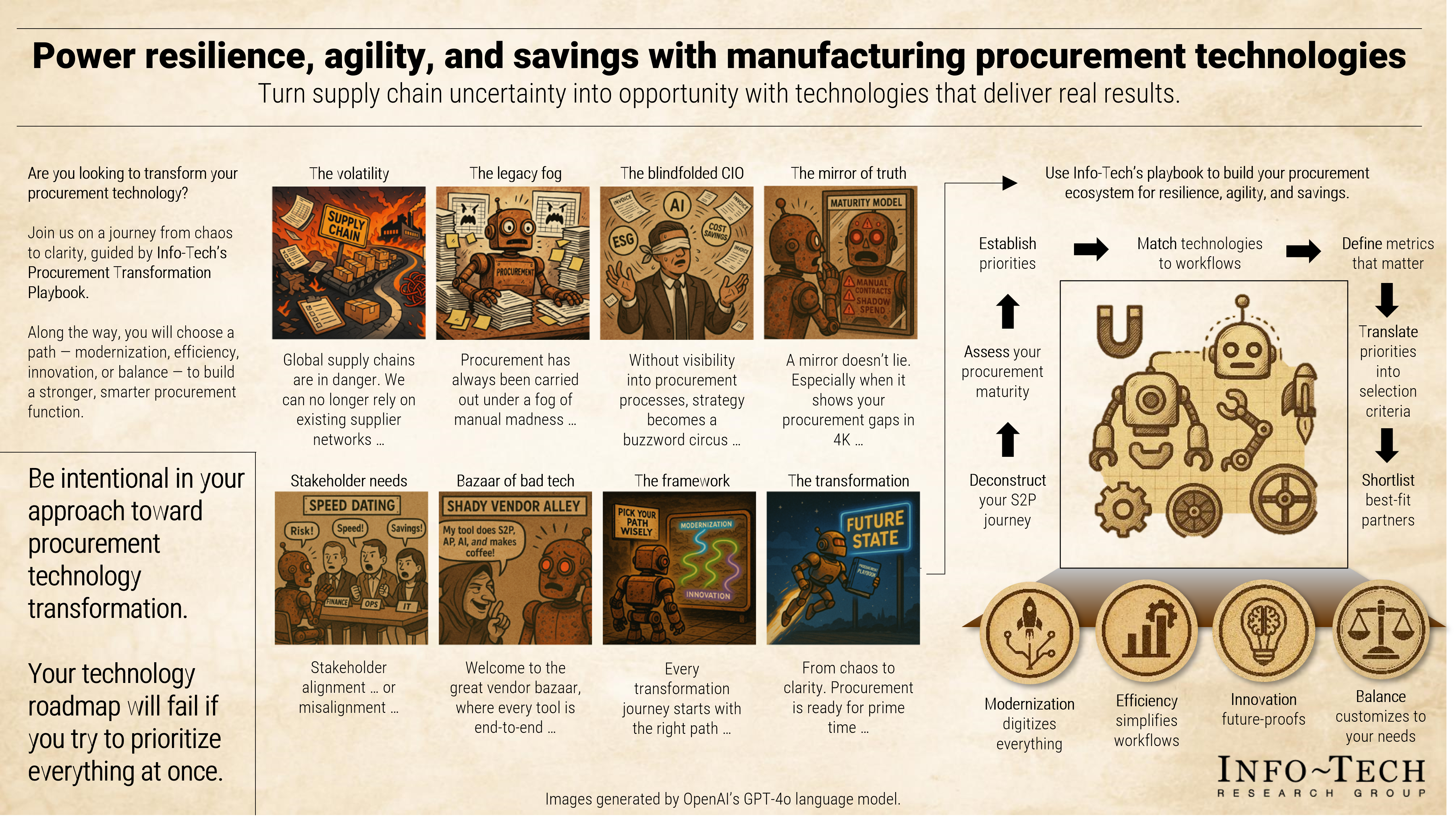

Power Resilience, Agility, and Savings With Manufacturing Procurement Technologies

Turn supply chain uncertainty into opportunity with technologies that deliver real results.

Analyst perspective

Turn supply chain uncertainty into opportunity with technologies that deliver real results.

In today’s manufacturing environment, volatility has become the new normal. Disruptions caused by policy, geopolitical tensions, raw material shortages, inflation, and demand swings are putting unprecedented pressure on supply chains. In response, procurement has moved from being a tactical back-office function to a strategic lever for operational stability and cost control. Yet many manufacturing organizations have not fully modernized this function, and that leaves them vulnerable. For CIOs seeking to build resilience and agility into their operations, now is the time to examine how digital procurement technologies can play a transformative role.

Advanced procurement tools now offer powerful capabilities in supplier risk assessment, spend visibility, contract lifecycle management, and predictive analytics. These technologies not only help reduce costs but also mitigate supply disruptions, enforce compliance, and enable faster decision-making across sourcing and manufacturing teams. The convergence of procurement and IT is no longer optional; it’s a necessary response to the complexity and speed of modern manufacturing.

The procurement technology landscape includes a wide range of solutions, from niche tools like e-sourcing and supplier onboarding platforms to integrated source-to-pay (S2P) suites that touch ERP, finance, and logistics systems. For CIOs unfamiliar with these systems, it can be difficult to determine where to begin, which technologies provide the most strategic value, and how to align them with broader digital transformation goals. This research aims to demystify the procurement function for manufacturing CIOs. It explores the key stages of the sourcing and procurement lifecycle, highlights where volatility has the greatest impact, and outlines the technologies that can mitigate risk and unlock value.

Shreyas Shukla

Principal Research Director, Industry

Info-Tech Research Group

Executive summary

Your Challenge

Policy changes have injected uncertainty into procurement operations. Tariffs on imports are leading to halted orders and forcing companies to seek alternative sourcing options quickly.

Procurement execution relies on specialized knowledge and supplier relationships. Many of these functions are carried out without the use of integrated systems, leading to inefficiencies such as redundant supplier contracts or missed opportunities for cost savings.

Manual processes and lack of advanced analytics slow operations, increase errors, and limit visibility into supplier performance and cost-saving opportunities.

Common Obstacles

Procurement has traditionally been viewed as a finance or operations function. Without a clear understanding of procurement processes, CIOs sometimes find it difficult to identify which solutions will drive the most value.

Procurement, finance, and operations often use disconnected, outdated, and manually managed tools. This fragmentation makes it difficult for CIOs to get a unified view of spend, supplier performance, and risk.

Procurement transformation has consistently seen underinvestment in specialized technology and analytics given its dependency on personal relationships, collaboration, and exception-based decision-making.

Info-Tech’s Approach

Make procurement transformation a strategic IT priority. CIOs must elevate procurement transformation to a core pillar of the enterprise IT agenda, alongside initiatives like automation, cybersecurity, and customer experience.

Map source-to-pay processes and identify gaps. CIOs should lead a structured review of the entire S2P lifecycle to identify bottlenecks, manual workarounds, compliance risks, and system inefficiencies.

Invest in modern procurement technologies. CIOs should evaluate best-fit technologies that align with the organization's sourcing strategy and integrate well with existing systems.

CIOs play a critical role in enabling procurement transformation by modernizing infrastructure and ensuring interoperability between platforms. A modern procurement technology landscape not only boosts operational efficiency but also empowers the organization with accurate, timely insights that are essential for navigating market volatility.

Your Challenge

Policy changes have injected uncertainty into procurement operations.

Tariffs on imports are leading to halted orders and forcing companies to seek alternative sourcing options quickly. For manufacturers, the sudden imposition of tariffs on raw materials or critical components can drastically alter the economics of sourcing decisions, halting inbound shipments midstream or rendering existing supplier relationships unsustainable. The absence of automated risk detection or scenario-planning tools exacerbates this challenge, making it difficult to evaluate the cost, quality, and lead time trade-offs of switching suppliers on short notice.

Procurement execution relies on specialized knowledge and supplier relationships.

Procurement teams often depend heavily on the institutional knowledge of category managers and supplier relationship owners who hold critical sourcing insights and negotiation experience. However, when these insights reside in email chains, spreadsheets, or the minds of individual staff, organizations risk duplication of effort, inconsistent contract terms, and fragmented supplier engagement. Without integrated systems, procurement teams can unintentionally create overlapping supplier contracts, pay non-preferred rates, or miss out on volume discounts. This siloed execution model also undermines compliance and makes it difficult to scale best practices across teams or regions.

Manual processes and lack of advanced analytics slow operations, increase errors, and limit visibility into supplier performance and cost-saving opportunities.

Manual actions not only introduce human error but also consume valuable cycle time and create bottlenecks that affect the entire supply chain. Furthermore, the absence of advanced analytics means that procurement teams operate with limited visibility into historical trends, supplier scorecards, or cost-reduction opportunities across categories.

Procurement must become more agile and intelligence-driven, supported by unified platforms that connect sourcing, contracting, and supplier performance in a shared digital environment.

Manufacturers are gearing up for significant supply chain disruption

Manufacturers are bracing for major supply chain disruptions driven by geopolitical tensions, shifting trade policies, labor shortages, and increasing material volatility. Companies recognize that traditional sourcing and procurement strategies are no longer sufficient to ensure stability and resilience. As a result, many are accelerating investments in digital procurement, supplier diversification, and risk analytics to adapt to a more unpredictable global environment.

Manufacturers are preparing for turbulent times ahead.

- 90% of businesses lack supply chain visibility.

- 52% of US businesses plan to nearshore in 2025.

- 33% of businesses worldwide expect supply chain disruptions in 2025. (Source: QIMA, 2025)

Manufacturers continue to deal with challenges from previous years.

- 53% of businesses struggled with rising prices.

- 33% of US businesses struggled to ensure consistent product quality in 2024.

- 25% of businesses found it hard to keep up with the growing body of supply chain and product laws.

Manufacturers are not very optimistic in their outlook for the short term.

- US trade policies are causing significant concern.

- Businesses expect to raise prices and source from alternative locations.

- Trade escalation with China is bound to have significant repercussions.

“… the most likely winner in a trade war between US and China is every other sourcing region” (Source: QIMA, 2025).

Common Obstacles

Procurement has traditionally been viewed as a finance or operations function.

Procurement's historical alignment with finance or operations has led many organizations to exclude it from broader digital transformation efforts. As a result, the lack of visibility into sourcing, supplier negotiation, contract lifecycle management, and strategic procurement planning makes it challenging for IT leaders to assess which procurement technologies would generate the greatest return on investment or operational impact. Without a strategic seat at the table, procurement is often overlooked during system architecture planning, and critical process gaps are left unaddressed.

Procurement, finance, and operations often use disconnected, outdated, and manually managed tools.

This fragmented environment makes cross-functional visibility nearly impossible, resulting in procurement teams managing suppliers in isolation, finance reconciling spend manually, and operations adjusting inventory without upstream coordination. The lack of integration among key systems means that CIOs are left piecing together inconsistent data from disparate sources. As a result, enterprise leaders struggle to answer foundational questions about supplier risk exposure, cumulative spend by category, or contractual compliance.

Procurement transformation has consistently seen underinvestment in specialized technology and analytics.

Procurement has often been perceived as too relational or judgment-based to benefit from structured systems. Many organizations believe that procurement success depends more on negotiation skill and interpersonal rapport than on digital tools. As a result, investments in procurement-specific platforms are frequently deprioritized in favor of more visible transformation projects in finance, sales, or manufacturing. This underinvestment creates a cycle of inefficiency and missed opportunity in which procurement teams remain overburdened by manual tasks and unable to leverage data to inform decisions.

CIOs must actively engage with procurement leaders and reframe procurement technology as a strategic enabler to enhance collaboration, accelerate execution, and scale data-driven decisions.

Procurement is in the spotlight and will need to transform quickly

Procurement is moving from a back-office function to a strategic centerpiece as manufacturers face mounting pressures around cost, risk, and supply chain resilience. With executives demanding faster, smarter, and more transparent sourcing decisions, procurement teams must rapidly modernize their processes, technology, and supplier strategies. Organizations that transform procurement now will be better positioned to drive competitive advantage in an increasingly volatile market.

Procurement contributes to organizational competitiveness through:

Strategic sourcing of raw materials

Procurement ensures reliable, cost-effective sourcing of materials to support production and reduce supply chain risks.Supplier relationship management

Effective supplier relationship management builds trust and collaboration to strengthen supply chain resilience and drive continuous improvement.Inventory management and optimization

Optimizing inventory helps balance supply and demand, reduce costs, and improve efficiency through accurate forecasting and lean management strategies.Logistics and distribution

Optimized logistics and distribution enable timely, cost-effective delivery of goods, boosting customer satisfaction and operational performance.Continuous improvement and innovation

Procurement drives continuous improvement and innovation by analyzing performance, reducing costs, and identifying opportunities for strategic growth.

(Source: Accelerate)

Procurement is indispensable to manufacturing.

“Procurement is fundamental” and spans everything from “day-to-day purchases to measuring sustainability to future-proofing operations for long-term growth. It’s a wide spectrum of mission-critical responsibilities, spanning all business functions” (Alexandre Gagnon, VP, Amazon Business Worldwide, in Supply Chain Management Review, 2024).

Info-Tech’s Approach

Make procurement transformation a strategic IT priority.

Procurement modernization should be embedded into the broader IT strategy. This means dedicating architecture, integration, and data governance resources to source-to-pay initiatives and aligning procurement technology goals with KPIs such as cost-to-serve, supplier resilience, ESG compliance, and time-to-market. Elevating procurement empowers IT leaders to close system gaps, unlock working capital, and build more responsive, risk-aware supply networks, all of which are mission-critical in today’s environment.

Map S2P processes and identify gaps.

CIOs should involve procurement, finance, and operations stakeholders to capture all edge cases, manual workarounds, and pain points. CIOs should document the data handoffs, system redundancies, and compliance blind spots that hinder efficiency or create risk exposure. This process map becomes the blueprint for transformation by guiding technology decisions, integration strategies, and process redesign.

Invest in modern procurement technologies.

Procurement transformation requires investments in specialized best-fit technologies that enhance supplier collaboration, decision-making, and visibility across the value chain. CIOs play a critical role in evaluating these tools for their functional capabilities and their interoperability. With the right mix of core and modular technologies, CIOs can transform procurement from a fragmented process into a cohesive, data-driven engine of value creation.

CIOs must ensure that procurement transformation is grounded in operational reality and linked to tangible business outcomes.

Manufacturers have already begun to identify and utilize opportunities to improve procurement

Manufacturers are increasingly recognizing procurement as a critical lever for operational and financial performance as well as supply chain resilience. Many have started streamlining sourcing processes, investing in digital tools, and improving supplier collaboration to reduce costs and enhance agility. By focusing on data-driven decision-making and aligning procurement with broader business goals, they’re turning what was once a support function into a strategic advantage.

Manufacturing procurement is stuck in a time warp.

- 96% of organizations are working to speed up procurement processes (aPriori/IndustryWeek, 2024).

- 70% of businesses still rely on email to manage procurement (aPriori/IndustryWeek, 2024).

- 69% of businesses take over a month to complete procurement (aPriori/IndustryWeek, 2024).

Procurement digitization has become a priority.

- 83% of global CPOs are considering digitizing their procurement processes (Procurement Tactics, 2025).

- 68% of businesses agree that connecting data systems is very important (aPriori/IndustryWeek, 2024).

- 52% of businesses are already using an off-the-shelf software solution (aPriori/IndustryWeek, 2024).

CPOs have begun taking action to add value to the business:

- By actively working toward increasing levels of supplier collaboration (61%).

- By standardizing policies, processes, systems, and data (85%).

- By using flexible automation tools (e.g. low-code/no-code and self-service) and methods (e.g. Agile approaches for iterative design/build/realize) (68%).

“… supplier collaboration is the top value-enabling strategy for CPOs, and those not prioritizing focus there may want to revisit how they can further enhance that capability” (Deloitte, 2023).

Volatility, disruption, and competition is pushing new procurement trends into the mainstream

Rising volatility, frequent disruptions, and intense global competition are accelerating the need for procurement transformation. Manufacturers can no longer rely on reactive manual processes to manage increasingly complex supply chains. To stay competitive, they must modernize procurement with digital tools, stronger supplier strategies, and more agile, data-driven decision-making.

Organizations are actively transforming how their procurement teams perform.

Focus Area |

From |

To |

How Technology Helps |

| Supply chain | Managing suppliers | Reshaping value chains | Technology enables real-time supplier visibility and collaboration across the value chain. |

| Margins | Cost and revenue optimization in silos | Cross-functional margin optimization | Analytics platforms connect cost and revenue data across functions to optimize margins holistically. |

| Resilience | Assume security of supply | Mitigate risk of supply shortages and disruptions | Risk management tools and predictive analytics proactively identify and mitigate supply disruptions. |

| Volatility | Reactive cost management and pass-through to customers | Anticipating and predicting price changes to outperform the market | AI-driven forecasting tools anticipate market price changes for smarter, proactive procurement strategies. |

| Technology | Data in silos | Insights from analytics | Integrated analytics unify data sources to provide actionable business insights. |

| Digitization | Manual processes, spreadsheets | Business spend management software or Integrated S2P platforms | Automation platforms digitize manual workflows to streamline procurement operations end-to-end. |

| Organization | Siloed, function-specific roles | Multifaceted roles with a focus on problem solving | Collaboration tools and integrated platforms break down silos and support cross-functional teamwork. |

| Talent | Back-office support function | Strategic value partner to the organization | Advanced procurement technologies elevate procurement's role from transactional to strategic through insights and innovation. |

(Source: McKinsey & Company, 2023)

Organizations are empowering CPOs by allowing them to redefine their playbook.

“Never before has procurement been core to so many executive committee–level priorities. We now have a real seat at the top table. And this is not a temporary situation — this is how we will operate going forward” (CPO of a manufacturing company).

“Volatility in the markets is at a level we have not seen before … Procurement’s ability to adapt to these changes and monetize that volatility will be absolutely crucial for success” (CPO of a pharma company).

Procurement strategies tailored for manufacturing environments differ from other industries in several ways

Procurement strategies for manufacturing are uniquely focused on securing a consistent, cost-effective supply of raw materials, components, and services that directly impact production lines. Unlike other industries, manufacturing procurement must balance quality, lead times, inventory levels, and supplier reliability with precision. Strategies often emphasize long-term supplier partnerships, risk mitigation, and operational efficiency to ensure uninterrupted manufacturing output and competitive advantage.

Strategies

Manufacturers utilize unique procurement strategies for their operational needs:- Centralized procurement: Centralize purchasing to coordinate suppliers, manage contracts, and leverage scale.

- Decentralized procurement: Empower local sites or regions to make procurement decisions based on specific needs.

- Third-party procurement: Engage external experts to enhance capabilities, access specialized skills, and optimize value.

- Spot buying: Facilitate quick, low-volume purchases to meet urgent, short-term material needs.

- Just-in-time procurement: Order inventory in small, timed batches to reduce storage and carrying costs.

- Automated procurement: Use digital platforms, IoT, and AI to streamline and optimize procurement workflows.

Processes

Procurement processes in manufacturing environments utilize some common steps:- Supplier evaluation: Assess potential suppliers based on cost, quality, reliability, location, and sustainability.

- Vendor selection: Choose suppliers through a balanced review of key selection criteria.

- Contract negotiations: Finalize terms on pricing, lead times, quality standards, and penalties before contracting.

- Purchase order and tracking: Issue detailed POs and monitor order status to ensure on-time delivery.

- Quality inspection: Inspect received goods to confirm they meet required quality standards.

- Inventory and payment: Store approved goods properly and process supplier payments per agreed terms.

- Supplier scorecards: Track vendor performance through KPIs to drive ongoing improvements.

Outcomes

Procurement enables specific supply chain outcomes:- Enhanced visibility: Integrate procurement data to gain real-time insight into material flows across the supply chain.

- Improved collaboration: Foster open communication among suppliers, logistics partners, and internal teams to support transparency and shared decisions.

- Proactive risk management: Build supply resilience through supplier diversification, scenario planning, and continuity strategies.

- Higher agility: Use flexible contracts and policies to quickly adapt procurement activities to changing priorities.

- Innovation impetus: Drive new product and service development through co-innovation with suppliers.

- Sustainability goals: Partner with suppliers to source eco-friendly materials and promote circular economy practices.

Before you proceed

This research is designed to guide CIOs and procurement leaders through actionable strategies to transform source-to-pay capabilities, integrate fragmented systems, and future-proof supplier collaboration.

Before acting on the recommendations outlined, readers should take time to prepare the organization thoughtfully, ensuring that the right participants, structures, and expectations are in place to achieve a successful transformation journey.

To get full value from this research and its accompanying tools, organizations should be prepared with:

- The right representation from procurement, finance, operations, IT, and risk/compliance to ensure that modernization efforts address full lifecycle needs.

- Participation from frontline sourcing managers, buyers, contract owners, AP specialists, and supplier managers.

- An inventory of all procurement-related systems and knowledge of the structure of critical data.

This research is designed for manufacturers of all sizes and across all sectors, from discrete to process industries. Whether operating regionally or globally, the insights and recommendations provided are intended to support organizations at any stage of their procurement modernization journey.

Enhance your operational readiness

If you are new to the world of procurement technology:

- See current procurement workflows in action. Firsthand exposure will reveal system gaps and user pain points faster than reports will.

- Interview procurement users at different levels. Don’t rely on executive summaries. Schedule short, focused conversations with buyers, category managers, and AP clerks. Their real-world frustrations will sharpen your understanding of modernization priorities.

- Build a simple procurement systems inventory sheet. List all systems used by procurement and note the owner, primary use, major gaps, and how (or if) it integrates with others. This view is invaluable for spotting overlaps, gaps, and silos early.

While this research will cover procurement S2P processes and concepts in detail, the resources below will strengthen your readiness to transform facets of procurement in your organization.

If you are looking to dive deeper into contract lifecycle management processes and tools, see Design and Build an Effective Contract Lifecycle Management Process.

If you are looking for scalable best practices from the world of IT contract pricing and negotiation, see Price Benchmarking & Negotiation.

If you are looking to compare capabilities of real-world procurement solutions, see our SoftwareReviews categories on Strategic Sourcing, Procurement Analytics, and Proposal Management.

Info-Tech’s methodology for mastering manufacturing procurement technologies

1. Deconstruct Your S2P Journey |

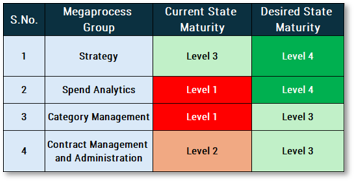

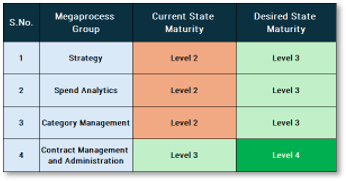

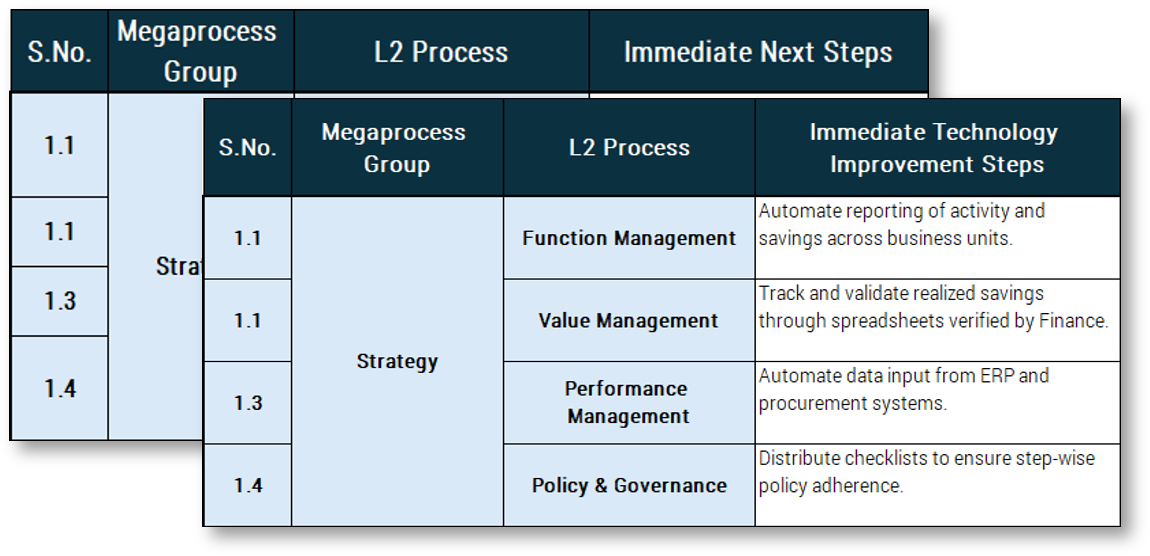

2. Assess Your Procurement Maturity |

3. Establish Priorities |

4. Match Technologies to Workflows |

5. Define Metrics That Matter |

6. Translate Priorities Into Selection Criteria |

7. Shortlist Best-Fit Partners |

|

Phase Steps |

|

|

|

|

|

|

|

Phase Outcomes |

Gain a full end-to-end view of how procurement processes operate today. Identify where inefficiencies, risks, and data silos are slowing down operations or causing value leakage. | Establish a structured baseline of procurement capabilities across multiple dimensions. Set improvement goals based on where your organization currently stands and where it needs to be. | Clarify what the organization needs most from procurement transformation. Set directional guardrails that will shape technology selection. | Understand how processes can be improved with the right tools. Highlight where modernization, efficiency, and innovation gains are possible with targeted investments. | Create a clear, agreed-upon set of success metrics that measure the impact of procurement transformation. Ensure all investments and changes are linked to visible improvements. | Ensure that technology decisions are driven by value-aligned criteria. | Learn from the successes of other organizations. Identify vendor options that match your chosen direction and create a focused shortlist for next steps. |

Blueprint deliverables

Each step of this blueprint is accompanied by supporting deliverables to help you accomplish your goals.

Key deliverables:

Manufacturing Procurement Technology Recommendation Tool

This tool is designed to help you:

- Systematically assess your current procurement technology maturity across key S2P functions.

- Define your desired end state led by user needs.

- Receive tailored recommendations aligned to technology transformation based on your objectives — modernization, efficiency, innovation, or a balanced approach.

The tool is intended to provide a guided, repeatable framework that helps organizations align procurement transformation efforts with business goals, operational realities, and digital readiness.

Using the Manufacturing Procurement Technology Recommendation Tool

Understand the maturity of your processes.

Understand the maturity of your technologies

Establish a transformation approach by choosing the philosophy that best meets your needs.

Receive detailed recommendations on how to improve your processes and technologies that require investments.

Blueprint benefits

IT Benefits

- Clarifies requirements early: Helps CIOs and IT teams design smoother, scalable integration between procurement, ERP, finance, and supplier systems.

- Improves technology selection precision: Equips IT leaders with structured evaluation frameworks (criteria, maturity models, transformation themes) to choose fit-for-purpose procurement solutions, not just “best marketed” ones.

- Reduces future technical debt: Guides organizations to modernize processes and data before automating, avoiding the buildup of siloed or patchwork system architectures.

- Strengthens cybersecurity and data governance: Reinforces the importance of securing supplier data, contract information, and financial transactions within integrated procurement systems.

- Positions IT as a strategic business enabler: Moves IT’s role from backend system maintenance to strategic support of procurement-driven savings, risk management, and supply chain resilience.

Business Benefits

- Accelerates procurement transformation outcomes: Provides a clear roadmap to move from manual, fragmented procurement activities to digitally enabled, data-driven operations.

- Enhances supplier risk management and resilience: Improves visibility into supplier performance, financial health, and geopolitical risks, essential for navigating today’s volatile supply chains.

- Drives cost savings and efficiency gains: Identifies automation, predictive analytics, and sourcing optimization strategies that directly reduce procurement cycle times and costs.

- Strengthens compliance and reduces operational risk: Supports improved contract management, sourcing governance, and audit readiness through standardized, integrated procurement workflows.

- Positions procurement as a strategic growth driver: Shifts procurement from a tactical, transaction-driven function to a key contributor to innovation, competitive advantage, and environmental, social, and governance (ESG) leadership.

Insight summary

CIOs play a critical role in enabling procurement transformation by modernizing infrastructure and ensuring interoperability between platforms.

A modern procurement technology landscape not only boosts operational efficiency but also empowers the organization with accurate, timely insights that are essential for navigating market volatility.

CIOs must be intentional in their choice between modernization, efficiency, innovation, or a balanced approach toward procurement technology transformation.

Your technology roadmap will fail if you try to prioritize everything at once.

- Deconstruct Your S2P Journey

CIOs must align technology choices to specific improvements.

- Assess Your Procurement Maturity

CIOs must customize what “good” looks like for their company, sector, and scale.

- Establish Priorities

CIOs must understand that the direction they choose will imply different investments and change expectations.

- Match Technologies to Workflows

CIOs must prioritize fit-for-process, not just best-in-class, tools.

- Define Metrics That Matter

CIOs must build metrics into everyday workflows, not after-the-fact reports.

- Translate Priorities Into Selection Criteria

CIOs must tie criteria to target performance metrics.

- Shortlist Best-Fit Partners

CIOs must understand that vendor options are specialized. Selection based on chosen direction is key.

Measure the value of this blueprint

How can you measure the value of following Info-Tech’s approach?

The average IT consulting rate in the United States is $100 to $250 per hour.

The cost and effort involved in undertaking a procurement technology transformation exercise varies depending on the size and scope of the project. The average cost of a well-designed and well-executed procurement transformation exercise ranges from US$42,000 to US$56,000 at the lower end (assuming a two-member team charging an hourly average of US$100).

With Info-Tech Resources |

Without Info-Tech Resources |

|||

| Project Steps | Time | Average Cost (USD) | Time | |

1 |

Deconstruct your S2P journey. | 2 days | $6,000-$8,000 | 1 week |

2 |

Assess your procurement maturity. | 1-1.5 days | $6,000-$8,000 | 1 week |

3 |

Establish priorities. | 1 day | $6,000-$8,000 | 1 week |

4 |

Match technologies to workflows. | 1.5 days | $6,000-$8,000 | 1 week |

5 |

Define metrics that matter. | 1-1.5 days | $6,000-$8,000 | 1 week |

6 |

Translate priorities into selection criteria. | 1 day | $6,000-$8,000 | 1 week |

7 |

Shortlist best-fit partners. | 1.5-2 days | $6,000-$8,000 | 1 week |

| Effort | ‹ 2 business weeks | $42,000-$56,000 | 1.5-2 months | |

(Source: MOR, 2025)

This blueprint will accelerate your own procurement technology transformation exercise.

We include all the guidance, tools, and templates you need to successfully implement this program.

Reach out to advisory services for assistance as you work through the blueprint or request a workshop engagement and let us do the heavy lifting.

Info-Tech offers various levels of support to best suit your needs

DIY Toolkit |

Guided Implementation |

Workshop |

Consulting |

| “Our team has already made this critical project a priority, and we have the time and capability, but some guidance along the way would be helpful.” | “Our team knows that we need to fix a process, but we need assistance to determine where to focus. Some check-ins along the way would help keep us on track.” | “We need to hit the ground running and get this project kicked off immediately. Our team has the ability to take this over once we get a framework and strategy in place.” | “Our team does not have the time or the knowledge to take this project on. We need assistance through the entirety of this project.” |

Diagnostics and consistent frameworks are used throughout all four options. |

|||